Imagine a world where your business runs like a well-tuned engine — efficient, waste-free, with consistently high-quality outputs. For many organizations, this is more than a dream; it’s reality thanks to Lean Six Sigma. From manufacturing giants to financial institutions, businesses across industries have used this methodology to optimize their processes, save money, and improve customer satisfaction. But how does Lean Six Sigma work, and why is certification so vital for professionals seeking to drive meaningful change in their organizations?

This comprehensive guide will answer those questions and help you understand what Lean Six Sigma certification is, its various levels, and how it can transform both your career and your organization.

What is Lean Six Sigma Certification?

Lean Six Sigma combines two powerful methodologies to improve processes: Lean, which focuses on increasing efficiency by eliminating waste, and Six Sigma, which emphasizes quality control by reducing defects and variations. Together, they offer a structured, data-driven approach to solving complex business problems.

A Lean Six Sigma certification validates your ability to analyze processes and apply tools to improve business performance. It demonstrates to employers that you have mastered the principles and techniques needed to drive efficiency, ensure quality, and enhance customer satisfaction. Whether you're working in manufacturing, healthcare, finance, or any other industry, Lean Six Sigma provides universally applicable solutions.

By earning a Lean Six Sigma certification, you're not just learning theories; you're gaining practical skills that you can implement immediately to create measurable improvements in your workplace.

Understanding Belt Levels in Lean Six Sigma Certification

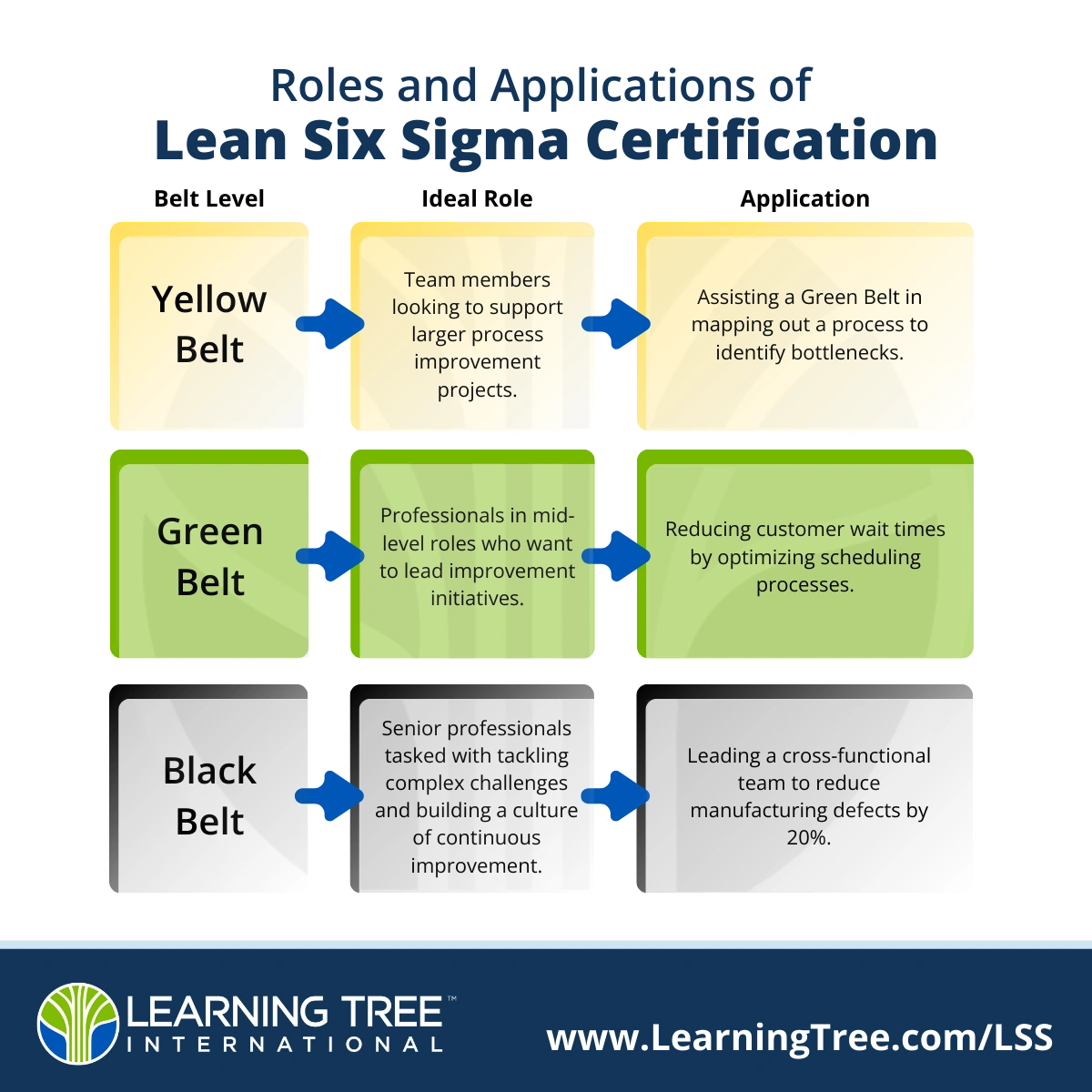

Lean Six Sigma certifications are offered in a hierarchy of "Belts," each representing a different level of expertise and responsibility. Here’s a breakdown:

Yellow Belt

The Yellow Belt is an entry point, designed for individuals who support Lean Six Sigma projects. Yellow Belts learn the basics of Lean and Six Sigma and participate in process improvement initiatives under the guidance of Green or Black Belts.

- Ideal for: Team members looking to support larger process improvement projects.

- Example Application: Assisting a Green Belt in mapping out a process to identify bottlenecks.

Green Belt

Green Belts have a more advanced understanding of Lean Six Sigma and can lead smaller projects independently. They specialize in using tools like the DMAIC process (Define, Measure, Analyze, Improve, and Control) and statistical analysis to solve moderately complex problems.

- Ideal for: Professionals in mid-level roles who want to lead improvement initiatives.

- Example Application: Reducing customer wait times by optimizing scheduling processes.

Black Belt

Black Belts are the experts and leaders in Lean Six Sigma. They oversee large-scale projects, mentor Green, and Yellow Belt holders, and drive organizational change. A Black Belt certification signifies mastery over advanced tools and techniques.

- Ideal for: Senior professionals tasked with tackling complex challenges and building a culture of continuous improvement.

- Example Application: Leading a cross-functional team to reduce manufacturing defects by 20%.

Earning your Belt progressively equips you with greater responsibilities and the ability to make a significant impact.

Skills Developed Through Lean Six Sigma Certification

Lean Six Sigma certification equips professionals with a blend of technical and soft skills. Here are some key competencies you’ll gain:

- Analytical Thinking: Learn how to identify inefficiencies and root causes of problems using data analysis tools like the Fishbone Diagram or Pareto Analysis.

- Problem-Solving: Master the DMAIC framework to systematically address issues and implement lasting solutions.

- Process Mapping: Visualize workflows to identify redundancies and streamline operations for better efficiency.

- Stakeholder Communication: Hone your ability to communicate findings and recommendations effectively, ensuring stakeholder alignment.

- Leadership: Develop skills to lead teams through change initiatives, while fostering buy-in and collaboration.

For example, a Green Belt might use control charts to monitor the progress of a process improvement, while a Black Belt is responsible for mentoring teams to ensure solutions are sustainable.

How Lean Six Sigma Contributes to Quality Control

At its core, Lean Six Sigma enhances quality by minimizing defects and making business processes more efficient. Here’s how it typically contributes to quality improvement:

Defect Reduction:

- By analyzing data and identifying the root causes of errors, Lean Six Sigma enables organizations to streamline their processes and deliver consistent, high-quality outputs. This methodology focuses on reducing variability, eliminating waste, and improving efficiency across all operations.

- Example: A healthcare provider successfully reduces diagnostic errors by implementing measures to improve the accuracy of data entry in patient records. By standardizing procedures and providing additional training for staff, they ensure that patient information is recorded correctly, leading to better treatment outcomes and enhanced patient safety.

Waste Elimination:

- Lean tools focus on identifying and eliminating waste in processes to improve efficiency and productivity. This can include reducing idle time in a manufacturing line, cutting down on excess inventory, or streamlining workflows to avoid unnecessary delays. By focusing on continuous improvement, lean tools aim to create more value with fewer resources.

- Example: A logistics company evaluates its supply chain to identify bottlenecks and inefficiencies. By reorganizing delivery routes, optimizing warehouse management, and leveraging data analytics, they successfully reduce transportation costs, minimize delays, and improve overall customer satisfaction.

Data-Driven Decisions:

- Organizations rely on metrics and statistical tools to ensure their decisions are objective and grounded in evidence rather than intuition. This approach helps minimize biases and improves overall efficiency.

- Example: A financial institution may use regression analysis to analyze customer data and identify key factors that predict creditworthiness, enabling them to optimize their credit approval processes and reduce the risk of default, while also speeding up decision-making for loan applications.

Do Employers Care Where You Get Your Lean Six Sigma Certification?

Yes, where you obtain your certification matters. Employers prefer certifications from the International Association for Six Sigma Certification (IASSC) to ensure credibility. IASSC has established rigorous standards and aligned its exams with the universally accepted Lean Six Sigma Body of Knowledge.

When it comes to Lean Six Sigma certification, the International Association for Six Sigma Certification (IASSC) stands out for its unique features and industry recognition. Choosing IASSC certification offers several advantages that set it apart from other certification providers:

Rigorous Standards:

IASSC has established stringent standards for Lean Six Sigma certification, ensuring that certified professionals possess a comprehensive understanding of the methodology. This demonstrates your commitment to excellence and dedication to continuous improvement.

Aligned with Industry Standards:

IASSC has aligned its certification exams with the universally accepted Lean Six Sigma Body of Knowledge. This alignment ensures that the certification covers the most relevant and up-to-date concepts, tools, and techniques used in Lean Six Sigma implementation.

Credibility and Trust:

Employers value certifications from reputable organizations like IASSC due to their established credibility. Holding an IASSC certification signifies that you have met the rigorous standards set by an internationally recognized certification body, which enhances your professional credibility and can give you a competitive edge in the job market.

Recognition by Global Organizations:

IASSC certifications are recognized and accepted by organizations worldwide. This recognition extends across industries, enabling you to pursue Lean Six Sigma opportunities in various sectors and geographic locations.

Choosing an IASSC certification demonstrates your knowledge, expertise, and commitment to quality, earning the trust of employers. An accredited certification shows you meet industry-recognized standards and have the skills to drive process improvements effectively. Employers value certifications from reputable organizations as a clear signal of competence and reliability.

Benefits of Lean Six Sigma Certification for Career Growth

Lean Six Sigma certification can open doors to new opportunities and higher salaries. According to data from leading certification bodies, certified professionals often see measurable career advancements. Here are some benefits:

- Higher Earning Potential: Certified professionals frequently earn 25-30% more than their non-certified counterparts.

- Expanded Career Opportunities: Certification is highly valued across industries, offering roles such as Process Improvement Manager, Operations Director, or Quality Assurance Engineer.

- Competitive Edge: The structured problem-solving skills and data-driven techniques offered by certification set professionals apart in the job market.

- Organizational Impact: Beyond personal benefits, certified individuals play a critical role in driving operational excellence within their organizations. For example, a certified Black Belt at a manufacturing company might lead an initiative to save millions annually by reducing production inefficiencies.

Achieve Your Full Potential with Lean Six Sigma Certification

Lean Six Sigma isn’t just about improving business processes — it’s about transforming the way organizations operate and the way professionals lead. From driving efficiency and quality to boosting your own career, Lean Six Sigma certification offers countless benefits. Whether you’re pursuing a first-time Yellow Belt or aiming for the advanced Black Belt, this methodology empowers you to create real, measurable change.

The next step is yours — discover accredited Lean Six Sigma courses, take a closer look at recognized certification providers like IASSC, and start enhancing your skill set today. Efficiency and excellence are within reach.